Services at L’Orfebre

- Gold Refining

-

Gold is probably the first metal worked by man. It made its appearance in the Neolithic period in the form of jewellery. Considered as a symbol of wealth due to its beauty and its shortage, early alchemists tried to make it themselves. However, as gold is never pure in its natural state it needs purifying. And this is the purpose of the REFINING.

L’ORFEBRE, S.A. uses two processes of an industrial scale for the refining of the gold at our current facilities. In the first part of the process, we get rid off most of its impurities refining it with "agua regia" (regal water), to get a 99.95% pure gold. This gold is then purified to a 99.99% through a process of electrolysis. (Also called Gold four 9).

-

- Refining with “Agua Regia”

-

The "Agua Regia" (Regal Water), is a mixture of nitric acid and hydrochloric acid. This "Regal Water", a term invented by the alchemists, dissolves the gold and separates the silver, being the main component found in gold. Rid of impurities, the dissolved gold quickly comes back to a solid state. At this stage, it does not yet contain traces of any elements, neither silver not copper.

L’ORFEBRE, S.A. can treat up to 50 kg of impure gold per day, obtaining a 99.95% of pure gold after our at refining process.

Depending on the needs, this pure solid gold will follow another refining or refining process, or will be made gold bars and bullions.

-

- Refining by electrolysis

-

In this phase of refining the gold by electrolysis, L’ORFEBRE, S.A. can obtain a 99.99% of gold purity. In order to achieve this, a minimum of 98.5% of pure gold is needed. This anode of the gold is given a bath, dissolved and placed on a cathode, allowing for almost all the impurities is made of to disappear.

L’ORFEBRE, S.A. will then melt this new high quality and colour gold into gold bars and/or bullions.

-

- Laboratory

-

To analyse the gold is an essential stage in all the different processes that take place in our refining facilities.

Indeed, L’ORFEBRE, S.A. analyses the gold both at the time of purchase as well as at different stages of the treatment process and tuning.

To this effect, L’ORFEBRE, S.A. has an analytical precision laboratory.

-

- Sampling

-

Sampling is done at the time of buying the gold

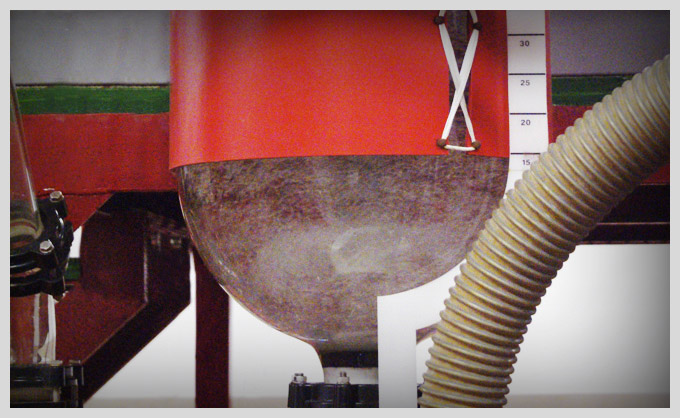

When gold reaches our refinery, it gets weighed and melted. Then a sample of the homogenised liquid is extracted and put in a quartz tube in order to determine the purity of the gold. This sample is then divided into three parts. The first part is used for the analysis, another part will be given to the supplier, and the third part will be properly stored and kept in our safe, in case a dispute about the quality or purity of the gold arises.

The supplier with the sample given can if he wishes, do a counter-analysis in a laboratory of his trust.

All stages of this process are properly filmed and recorded, so the supplier can have a total confidence in the event that can not be present at the time of the casting and analysing.

This sample also allows us to determine the parameters of the refining.

The content of the gold is also measured after different refining processes to ensure the result.

-

- Analysis

-

There are 2 methods L’ORFEBRE, S.A. uses in its laboratory for analysing the gold: the cupellation and the analysis by X fluorescence spectrometer (XRF: X-Ray Fluorescence).

Cupellation, also called fire assay, is a method invented in China several centuries before our times. The first time this was used as a verb, comes from the XII century. This method has developed a great deal since then, and has become a very well recognised method globally used.

L’ORFEBRE, S.A. uses IOS 11426 standards to do the cupellation analysis.

The sample is purified: Initial and final mass get compared to a 0.01 mg high precision scale in order to calculate its purity.

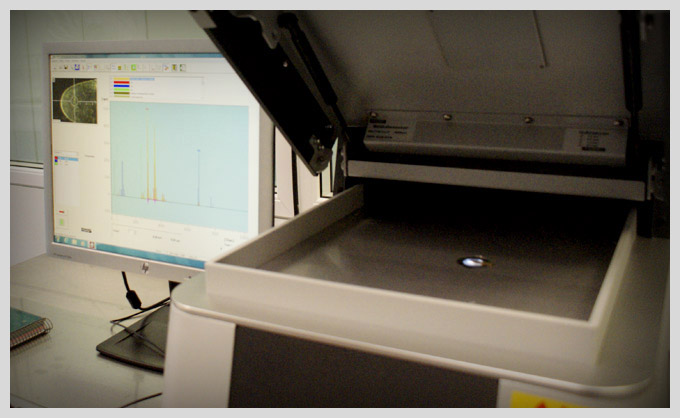

The XRF is a gold analysis method that uses utensils of great technology. The X-Ray Xan Fischerscope 250, allows us to analyse the composition of a sample in only three minutes, with an accuracy of up to 0.1 thousandth.

Contrary to cupellation, composition by XRF does not change the state of the sample. The system is fast, non-destructive, accurate and highly reliable.

-

- Transportation

-

L’ORFEBRE, S.A. can arrange the collection of the goods coming from different producer countries at the Barcelona Airport, in Spain.

It is essential, before the arrival of the precious metal at the airport, to have all the necessary documentation to process the entrance of it in Andorra.

We have a customs agent at the airport who works in total collaboration with the police and all of the local authorities at the airport.

We also have an agreement with an armoured vehicles company at the airport that transports values, and vehicles are escorted by security guards all the way until the arrival of the gold in Andorra.

-

Services & Products

Services & Products